Trusted Industrial Scales Brands Advised by Experts

Trusted Industrial Scales Brands Advised by Experts

Blog Article

Enhance Your Business Procedures With Reliable Industrial Scales

In today's competitive landscape, the accuracy of industrial ranges plays an essential role in boosting general business operations. As businesses look for to enhance efficiency, recognizing the various types of scales and their technical improvements becomes essential.

Relevance of Accurate Evaluating

Exact weighing is vital in various industrial applications, as even minor disparities can result in substantial operational inefficiencies and economic losses. Industries such as production, logistics, and food handling rely on precise measurements to guarantee product high quality, regulative conformity, and optimum source administration. Incorrect weights can result in overproduction, waste of raw materials, or insufficient supply, impacting profitability and customer complete satisfaction.

Furthermore, accurate weighing is important for safety and ecological conformity. In the chemical market, wrong dimensions can lead to improper blends, resulting in hazardous scenarios or legal ramifications. Furthermore, in the food market, specific evaluating is essential for sticking to nutritional labeling demands, making sure that customers receive precise info regarding the products they purchase.

The combination of dependable commercial ranges not only boosts operational effectiveness yet also sustains data-driven decision-making. Investing in high-grade industrial evaluating remedies is important for organizations intending to maintain a competitive edge in today's vibrant industry.

Sorts Of Industrial Scales

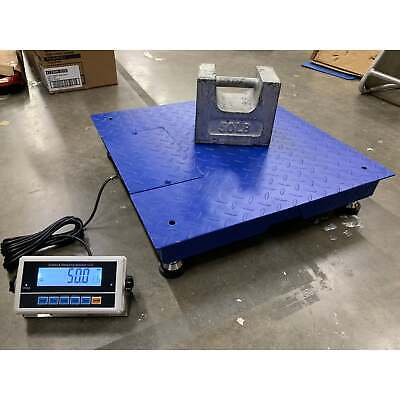

Industrial scales come in different types, each developed to satisfy particular evaluating requirements across various fields. Amongst one of the most usual types are system ranges, which supply a big evaluating surface ideal for heavy items, making them perfect for warehouses and making facilities. These scales often include electronic screens for very easy reading.

An additional type is bench ranges, which are usually smaller sized and portable, perfect for use in laboratories or retail atmospheres. They allow for quick dimension of smaller sized items while preserving precision. For applications needing the considering of liquids, storage tank ranges are particularly made to measure the weight of tank, guaranteeing exact supply management.

Crane scales are likewise significant; they are suspended from a structure to evaluate heavy products in commercial setups. Each kind of commercial scale serves a distinct function, enhancing operational efficiency across varied sectors.

Benefits of Modern Innovation

Additionally, modern-day commercial ranges often come furnished with connection functions that make it possible for smooth integration with other systems, such as inventory management and production tracking. This interconnectivity fosters a more cohesive workflow and minimizes downtime, as businesses can keep track of performance metrics and make data-driven choices without delay.

In addition, several modern scales provide customizable setups and straightforward interfaces, allowing drivers to adapt their equipment for details operational needs. Boosted longevity and durability versus extreme environmental problems further add to the long life and dependability of modern scales, guaranteeing they can endure the roughness of industrial usage.

Choosing the Right Tools

Various markets may need unique kinds of scales, such as flooring scales for heavy loads, bench scales for smaller sized things, or mobile ranges for versatility. Furthermore, thinking about the atmosphere in which the scales will be made use of is crucial. Equipment made use of in extreme environments might need to be rugged and immune to dust, dampness, or extreme temperatures.

One more vital element is the modern technology used in the ranges. Digital ranges usually provide boosted accuracy and convenience of use, while analog scales might suffice for less requiring applications. It is crucial to evaluate the scalability of the equipment, making certain that it can accommodate future growth or modifications in production processes.

Finally, services must think about the online visite site reputation and integrity of makers, as buying high-grade tools can bring about lasting price financial savings and enhanced functional efficiency.

Upkeep for Longevity

Normal maintenance is crucial for making certain the long life and ideal efficiency of commercial ranges. A methodical method to maintenance not only extends the life of the devices yet likewise assures precise dimensions crucial for functional efficiency.

Begin with regular inspections to recognize wear and tear, making certain elements such as lots cells and screens operate correctly. Calibration checks need to be carried out routinely, preferably after significant modifications in ecological conditions or adhering to hefty usage. Precise calibration is vital for conformity with sector standards and for preserving the integrity of weight dimensions.

Cleaning up is an additional crucial facet of maintenance. Dust, particles, and corrosive substances can hinder efficiency and bring about mistakes. Usage ideal cleaning agents and methods to protect delicate components. Additionally, it is a good idea to develop an upkeep timetable that tape-records each solution browse through, calibration, and any kind of repairs carried out. This paperwork aids in tracking devices efficiency and preparation for future upkeep demands.

Finally, educating personnel on proper usage and care techniques will certainly lessen the chance of operator error, additionally visit this website enhancing scale integrity. By prioritizing normal upkeep, companies can make certain that their industrial ranges stay a dependable property in their procedures.

Final Thought

In recap, the combination of dependable commercial scales is crucial for improving organization operations throughout various markets. Accurate evaluating not just minimizes inconsistencies but additionally optimizes inventory administration and makes certain compliance with market requirements. The choice of proper tools, paired with modern technological improvements, can dramatically boost performance and reduce functional prices. Normal upkeep and training more add to the durability and accuracy of these scales, fostering data-driven decision-making and ultimately supporting overall business success.

Industrial scales come in numerous types, each designed to satisfy particular considering requirements across various industries. Crane published here ranges are likewise significant; they are suspended from a framework to weigh hefty materials in industrial setups.Different sectors may require distinctive types of scales, such as flooring ranges for heavy tons, bench ranges for smaller products, or mobile ranges for flexibility - Industrial Scales. Digital ranges often use boosted accuracy and simplicity of usage, while analog scales might be enough for less requiring applications.In recap, the integration of trusted commercial ranges is essential for enhancing company operations across various industries

Report this page